We have a guest contribution today from Zvi Or-Bach, the President and CEO of MonolithIC 3D Inc. In this post, Zvi shares his perspective on where the industry is going.

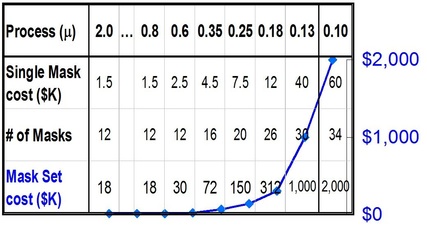

The first step of "heating the water" came as we moved to 0.65 micron node. After many years of stable mask cost at ~$1,500 per mask it moved up, almost doubling to ~$2,500. And making it even more painful, we moved from just two metal layers to multiple metal layers, increasing the over all mask set cost soon after. This was discussed in more details in a previous blog-post here.

The table below presents the mask cost trend since then.

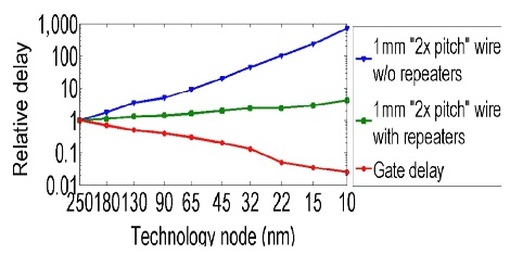

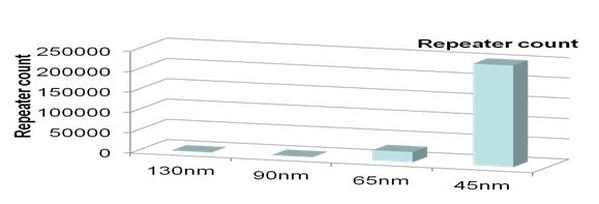

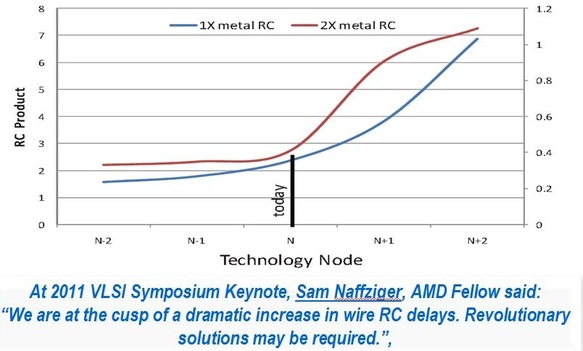

So we kept on "heating the water" and the interconnect issue popped up. We first introduced repeaters and larger drive, than moved to copper and recently to low-k. So we were able (at great cost) to push the issue for more than a decade but as we can see from the chart below - it is not going away.

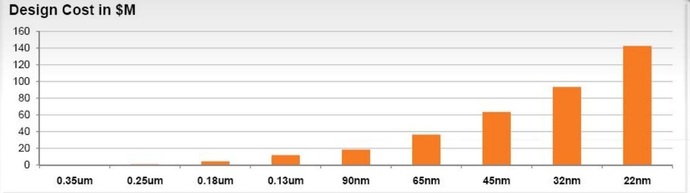

And in fact, it is starting to escalate and get pretty painful, as you can see from the charts below:

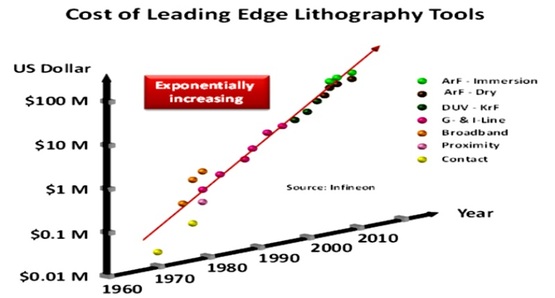

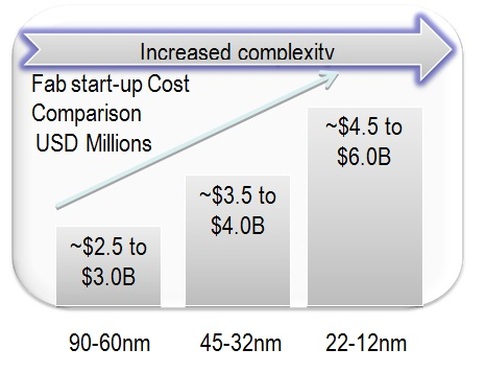

The increased cost of lithography is starting to dominate the cost of fabs. The following chart presents the escalating trend of fab costs:

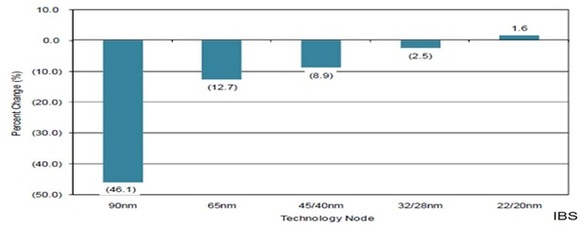

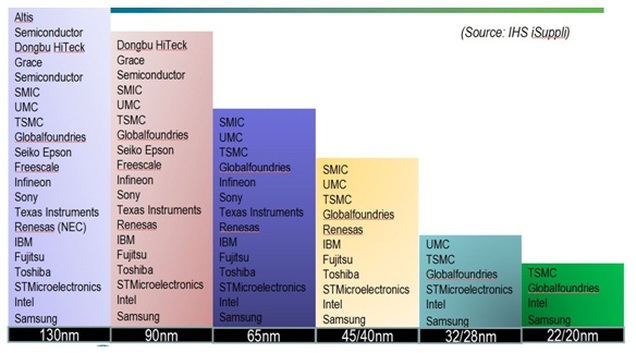

Not surprisingly, a trend we saw in the past in the number of ASIC vendors can now be seen in the number of semiconductor logic vendors, as presented in the following chart from iSuppli:

Yet we don't need to get boiled - we are not frogs, so let's not behave like them.

Lets slow down the heating and adopt a complementing path to maintain the integration trend (Moore's Law)

- the monolithic 3D IC.

RSS Feed

RSS Feed