Looking at the semi-equipment booking should be the first step in any attempt to assess future semiconductor trends. While talking is easy, spending billions of dollars is not. Vendors look deeply into their new design bookings and their future production needs before committing new dollars to long lead purchases for their manufacturing future needs. In the past decade it was relatively simple, as soon as a new process node reached production maturity vendors would place new equipment orders knowing that soon enough all new designs and their volume will shift to the new process node. But the Semi™ report seems to tell us that we are facing a new reality in the semiconductor industry – a Paradigm Shift.

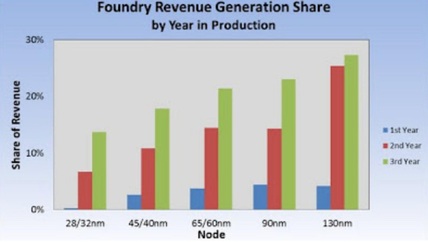

A while ago VLSI Research Inc. released the following chart with the question: Is Moore’s Law slowing down?

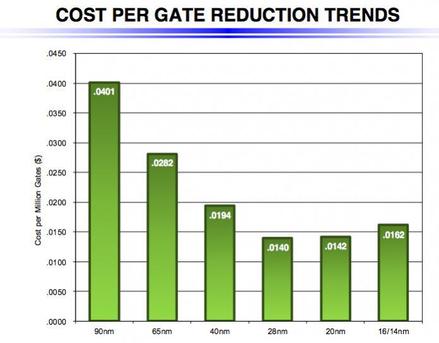

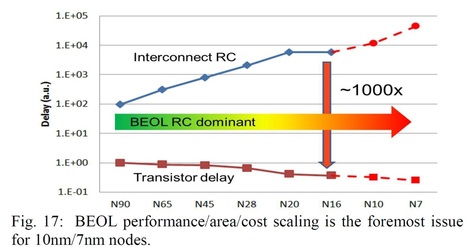

Just few weeks ago at the SEMI ISS conference, Handel Jones of IBS presented many very illuminating charts and forecasts. The following chart might be the most important of them and it is the revised calculation of per gate cost with scaling.

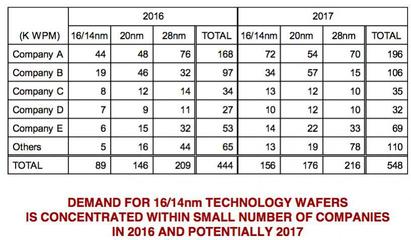

The following table, also from Jones, illustrates this new reality.

RSS Feed

RSS Feed