Direct wafer bonding is both desirable and required for low cost high yield monolithic 3D integration. “Direct” meaning that an extra layer, an intermediate layer, such as an adhesive, is not used. The bonding between the surfaces only involves the chemical bonds between the two surfaces. The simplest case for a conventional wafer fab, which has the highest probability of achieving high yield & low cost direct bonding, is oxide to oxide bonding. Oxide to oxide wafer bonding has the added advantage that a through layer via connection may not need an isolation liner, and is part of a process integration strategy that delivers a Thorough Layer Via (TLV) with processing ease and characteristics similar to a conventional BEOL metal to metal via.

Another enabler for monolithic 3D integration is a direct bonding process that has thermal exposures to the underlying layer or layers that does not exceed 400°C. This allows the use of conventional metallization and low-k dielectrics such as copper & carbon containing low-k oxides BEOL, rather than difficult to manufacture high temperature metals such as tungsten. Two additional advantages of low temperature bonding are avoiding any wafer deformation due to thermal expansion effects (greatly helps across the wafer alignment precision), and minimizing the thermal effects on the lower layer transistor hi-k metal gate stacks and junctions.

Many investigators, groups and companies have developed pre-bonding surface conditioning and post-bonding thermal treatments to control and optimize the bonding strength within the constrained thermal budget window (<400°C) and have achieved excellent bond strength’s greater than 1 J/m2. A sampling of the literature follows:

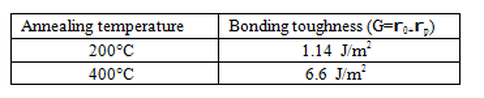

DiCioccio et al. at ICICDT 2010 [CEA-LETI-Minatec, Grenoble, USA] showed acceptable bonding strengths from bonded wafers with 5um copper pads that cover 20% of the area, the remainder is oxide to oxide, after a 2 hour 200°C or 400°C post bond anneal. The surfaces were carefully prepared with CMP.

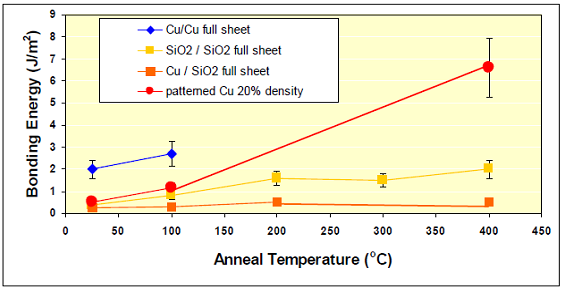

Radu et al. at the 2010 3DIC conference [Soitec Bernin, CEA-LETI-Minatec, Soitec USA], showed bonding energy data obtained from 200mm wafer bonding of Cu/Cu full sheet, SiO2/SiO2 full sheet, Cu/SiO2 full sheet, and pattered 5um Cu pads at 20% density. Oxide to oxide bonding at 200°C produces over 1 J/m2 bonding energy. The surfaces were carefully prepared with CMP.

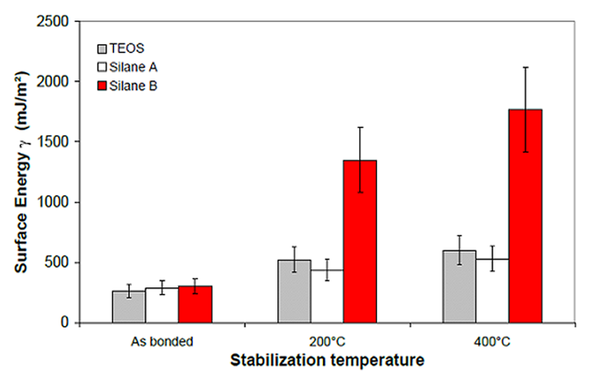

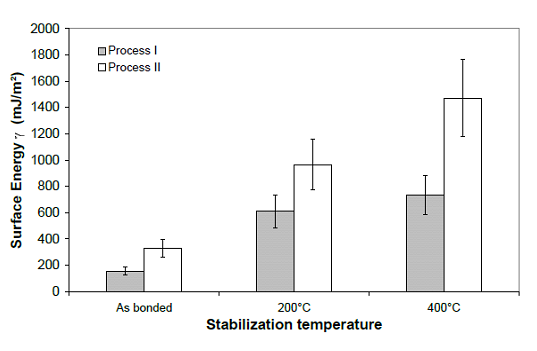

Gaudin et al. at 3DIC 2010 [Soitec Grenoble, Soitec USA, IBM Albany, IBM East Fishkill] utilized 300mm wafers with a backend CMOS process and deposited oxide layer acting as the bonding layer. Bonding surfaces were prepared with an optimized CMP process and post-bond annealing, thinning and grinding were successfully performed. Gaudin studied one TEOS-based oxide and two different condition sets for silane-based PECVD oxide. Silane condition B was certainly superior and exceeded the 1 J/m2 metric at both 200°C and 400°C.

Gaudin further influenced the bonding quality by conditioning the surface with wet chemical processing (Process I) and dry plasma processing (Process II).

Dragoi et al. at SPIE 2007 [EV Group] showed blank wafer data where a PECVD oxide was deposited, outgassed in a vacuum anneal at 300-400°C 1-3 hr anneal, CMP polished, nitrogen plasma activated, megasonic cleaned, vacuum bonded with 5kN force, then annealed for 1 hour at 300°C.

Dragoi successfully applied the process on 200mm Si on CMOS bond pairs.

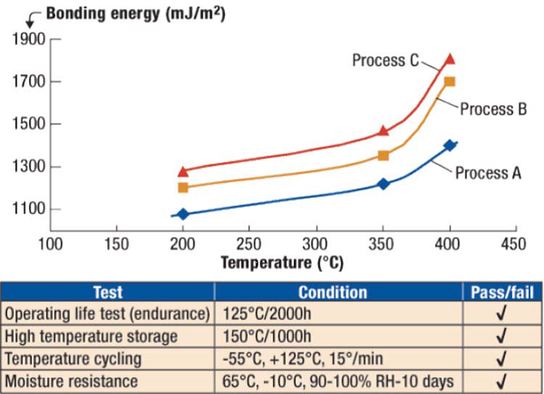

Sadaka et al. in electroiq.com (2010) [Soitec USA, CEA-DRT-LETI] showed 3 different processes (CMP/surface conditioning/planarization/cleaning). With 200°C, 350°C or 400°C post bond anneals, the target of 1 J/m2 was achieved.

Ziptronix talks about their DBI (Direct Bond Interconnect) technology as utilizing RIE surface cleans & porosity enhancement, NH4OH surface treatments, CMP to 0.5nm RMS, and obtaining bond energies >1 J/m2 at room temperature.

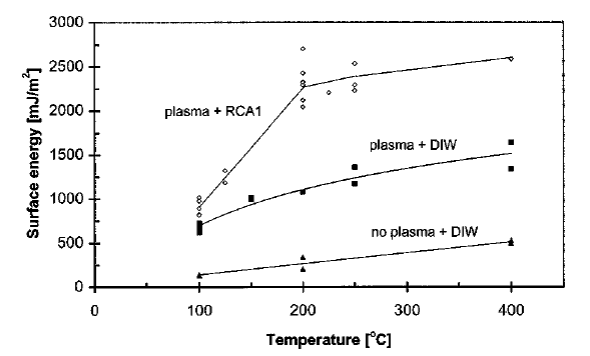

Henttinen et al. in Applied Physics Letters April 2000 [VTT Electronics, Finland; UC San Diego] demonstrated oxide to oxide bonding of silicon wafers with various plasma or RCA clean pretreatments, and post-bond thermal anneals.

In summary, a variety of investigators have shown processes capable of providing excellent wafer to wafer bond strengths.

References:

DICIOCCIO, L., et al., "Direct bonding for wafer level 3D integration", ICICDT 2010, pp. 110-113.

DRAGOI, et al., “Plasma-activated wafer bonding: the new low-temperature tool for MEMS fabrication”, Proc. SPIE, Vol. 6589, 65890T (2007).

RADU, I., et al., "Recent Developments of Cu-Cu non-thermo compression bonding for wafer-to-wafer 3D stacking", IEEE 3D Systems Integration Conference (3DIC), 16-18 Nov. 2010.

GAUDIN, G., et al., "Low temperature direct wafer to wafer bonding for 3D integration", 3D Systems Integration Conference (3DIC), IEEE, 2010, Munich, 16-18 Nov. 2010, pp. 1-4.

SADAKA, M., et al., "Building Blocks for wafer level 3D integration", www.electroiq.com, August 18, 2010.

www.ziptronix.com, DBI fact sheet

HENTTINEN, K. et al., "Mechanically Induced Si Layer Transfer in Hydrogen-Implanted Si Wafers," Applied Physics Letters, April 24, 2000, p. 2370-2372, Vol. 76, No. 17.

I.J. MALIK, et al., “The Genesis Process: A general layer transfer method for electronic applications,” Spring 10999 MRS Symp. Tech. Proc., 1999

F.J. HENLEY, et al., European Semiconductor, 25, Feb. 2000.

RSS Feed

RSS Feed