Do real men need to have a fab?

Will Apple and Qualcomm become IDMs?

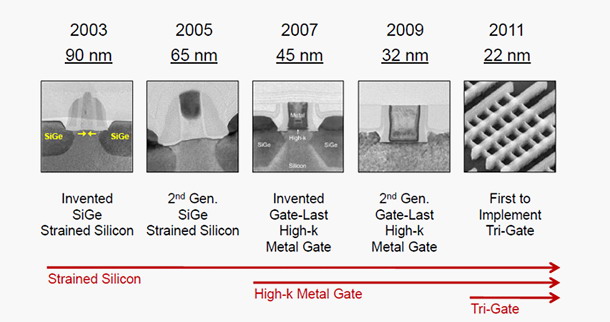

Let’s try to put things in order and analyze the situation thoroughly, especially from the point of view of process capabilities and performances. There are obvious differences between what Intel does and what the foundries do. For this discussion we will use TSMC to represent the foundries. Both companies, Intel and TSMC, are making logic devices so we can compare their respective capabilities in the logic arena. For the last few decades Intel has been the leader in the area of process technology with the introduction of several process innovations as shown in Figure 1.

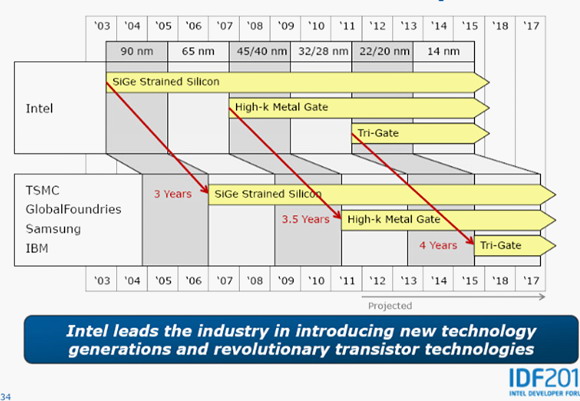

Figure 2 is Intel’s view of the gap between them and the foundries, which I mostly agree with.

Intel:

A “one product companyâ€, it is a company that thrives on the PC market with the high performance family of the microprocessors (including servers) as their main product line.

It is well known that their efforts into mobile devices has not (yet) been successful, even with the billions of dollars already invested.

The process technology machine is second to none; nobody can even get close to Intel’s transistor performance.

The foundries are continuously trying (unsuccessfully) to catch up with Intel

TSMC (as representing the foundries):

Running many different devices with multiple technology nodes and wafer sizes

Running hundreds of different products where some are high volume runners and some run only a handful of wafers per year.

Adjusting the process parameters for many of the products so that the yield will be optimum for each one of them. This could be a nightmare for an efficient fab operation…very different than what Intel is running in their fabs.

As mentioned at the beginning, an interesting situation has emerged within the last few months; the so called “the 28nm foundry crisisâ€. The situation came from an unforeseen huge demand for the just-introduced-to-production 28nm process. It is an unprecedented situation where the demand for a new node outstrips the current supply. All of the foundries are scrambling to increase production in order to satisfy the unhappy customers.

Here are some quotes to that effect by some of the major players.

- Qualcomm: “We are seeing very strong demand for our industry-leading Snapdragon 4, MSM8960, and other 28nm products,†Qualcomm's CEO Paul Jacobs told press and analysts during the company's earnings call late yesterday. 'Although the manufacturing yields are progressing per expectations, there is a shortage of 28nm capacity.

- Nvidia Corp’s CEO Huang: …“besides continuously increasing capital expenditures that the company ran into in the recent months will be accompanied by lower than expected gross margins in the forthcoming quarterâ€. The company blames low yields of the next-generation code-named Kepler graphics chips that are made at TSMC’s 28nm node.

- Mark Bohr, who is the director of process architecture & integration and senior fellow of technology and manufacturing group at Intel, told EETimes that “the foundry model is collapsing. Chipmakers like Qualcomm will not be able to use TSMC’s single 20nm processâ€.

TSMC: Producing 28nm in Fab 14(Phase 4, 5) and Fab 15 (phase 1, 2). Planning to move Fab 15 (phase 3, 4) to 28nm by the end of the year

GlobalFoundries: Running 32/28nm process in their Dresden fab and plan to move production on 32/28nm in their new Fab in Malta, NY

UMC: Ramping 28nm in their Fab 12A (phase 3, 4)

Samsung: The Korean Fab S1 is ramping 28nm production and rumors are that they will be converting line 14 (NAND Fab) to 28nm logic as well as the Austin NAND fab.

Several issues need to be addressed from this fiasco:

- What happened? Why this big and sudden capacity crunch?

- Are we setting ourselves up for a glut in 28nm capacity in 2013?

- Is some of the demand a result of double booking – a well known disaster in the making….

- Are Qualcomm and Apple going to be so disgusted with the situation that at the end of the day they will decide to follow the former AMD CEO Jerry Sanders’s saying “Only real men have fabs�

1. The foundries fell asleep at the switch when they misread the advanced technology that Intel was bringing up and that their main customers needed the performance that the 28nm brings. Also the big fiasco of gate first vs. gate last on HighK metal gate and the long time it took for them to understand and execute this new process (some are even still using the inferior oxide/poly gate).

2. It is typical to our industry (see the DRAM history) that when there is a shortage in one type of device/technology everybody is jumping the gun and increase production in an uncontrolled manner trying to capture more volume. At the end of the day there will definitely be an oversupply.

3. Rumors are because of the situation that there already is double booking (sounds familiar….)

Both Apple and Qualcomm can afford with all the cash they are sitting on to have their own fabs to mitigate this kind of disaster…Will they do that? I personally doubt it. It is uncharacteristic to their business practice: however, depending on underperforming foundries is not a desirable situation.

As for the future, the situation is not getting easier. Intel has already announced and started high volume production of the new 22nm using FinFET (Tri Gate) transistor, a whole new concept for a production transistor structure.

Would the foundries be ready for that or we will again see fumbling around the issue? Do we really need FinFET at 22(20) nm or not?

RSS Feed

RSS Feed