Entanglement Squared

"In quantum entanglement, two objects are connected by an invisible wave, like an umbilical cord, that allows them to essentially share the same existence. When something happens to one object, it immediately happens to the other, no matter how far apart they are."

Whether there actually is an entanglement or it is just a coincidence, the lithography challenge and the interconnect challenge seem to be affecting the semiconductor industry in coordination.

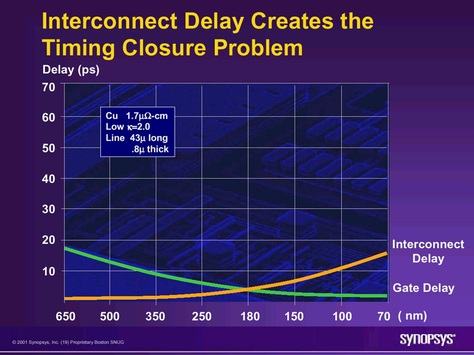

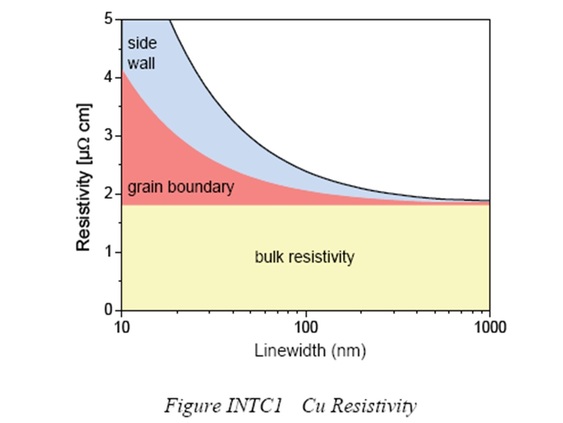

But scaling to about 0.18 micron brought us what we shall term an entanglement, which involved two inflection points. The first inflection point was the change over from transistor domination of circuit delay to interconnect domination of circuit delay.

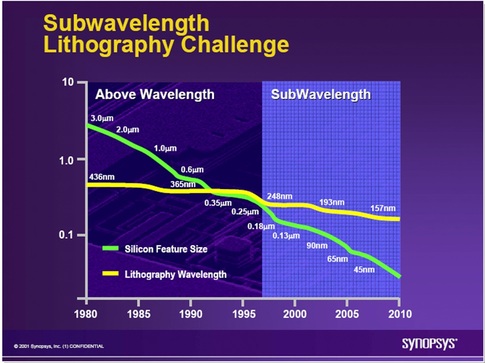

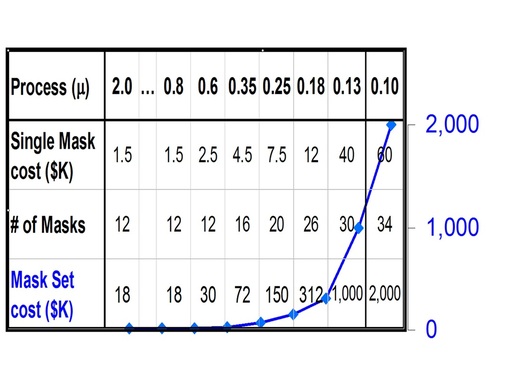

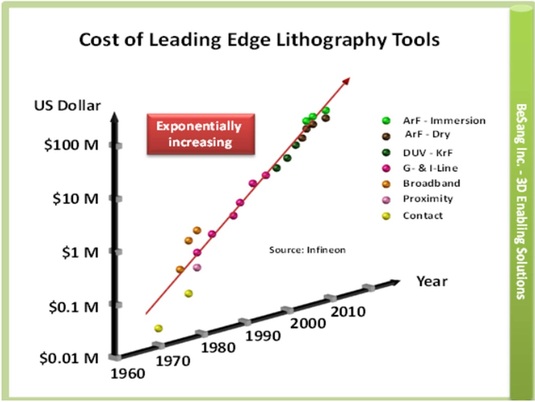

The second inflection point had to do with sub-wavelength lithography and brought other type of changes. First was the use of OPC and other types of reticle enhancement techniques. Then there were significant improvements of lithographic tools which involved moving from mercury lamps to excimer lasers and immersion lithography. These changes had a drastic effect on lithography equipment cost and, even more, on mask cost.

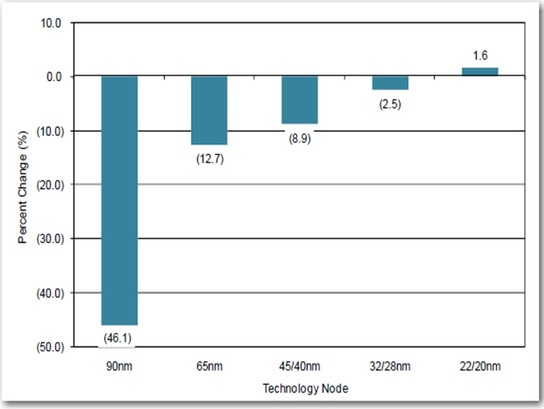

This first entanglement had a multiplicative effect on mask set cost as more metal layers required more masks, while each mask was getting more expensive. This is illustrated in the following table. (Please note that mask cost tends to get significantly reduced over time as the mask shop equipment gets depreciated)

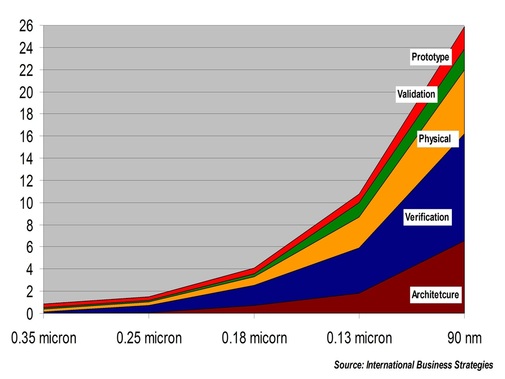

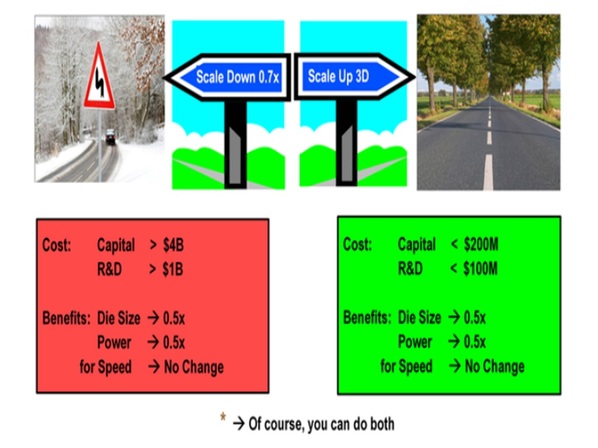

We now entering what seems to be a second entanglement, hence the title "entanglement squared" for this article.

On the lithography front it seems that whether we use double and triple patterning, or the long delayed EUV, the cost of lithography tools will dominate future fabs. An EUV tool is estimated to cost more than $100M.

RSS Feed

RSS Feed