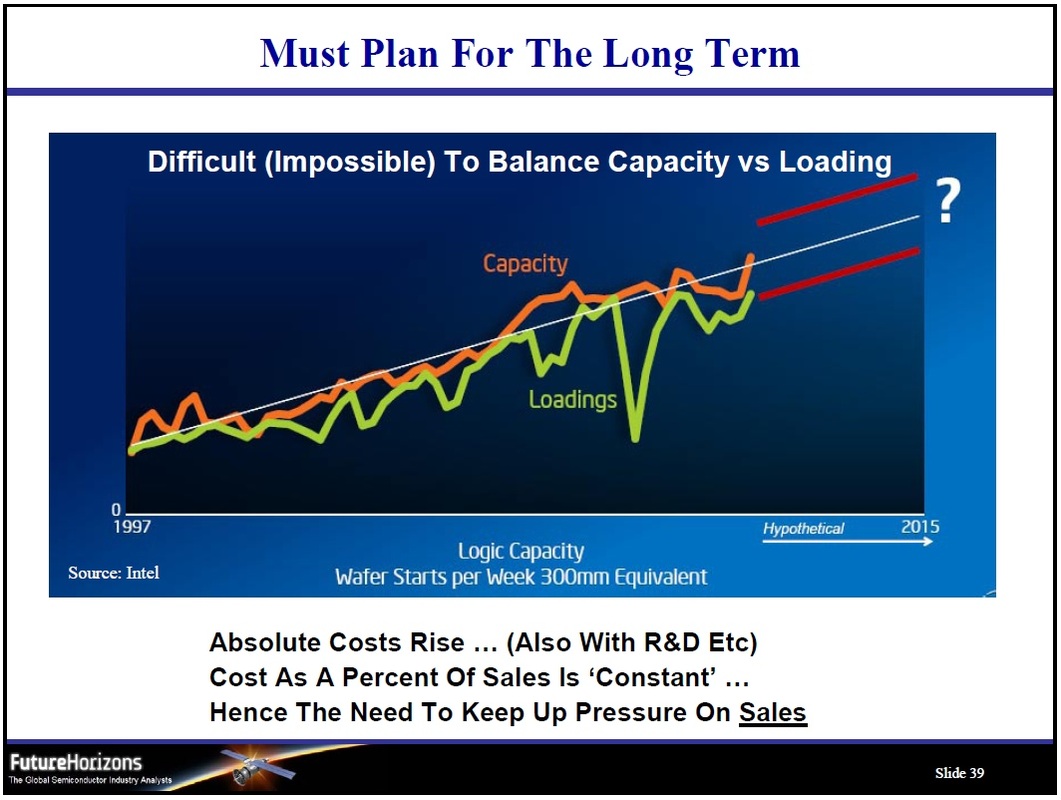

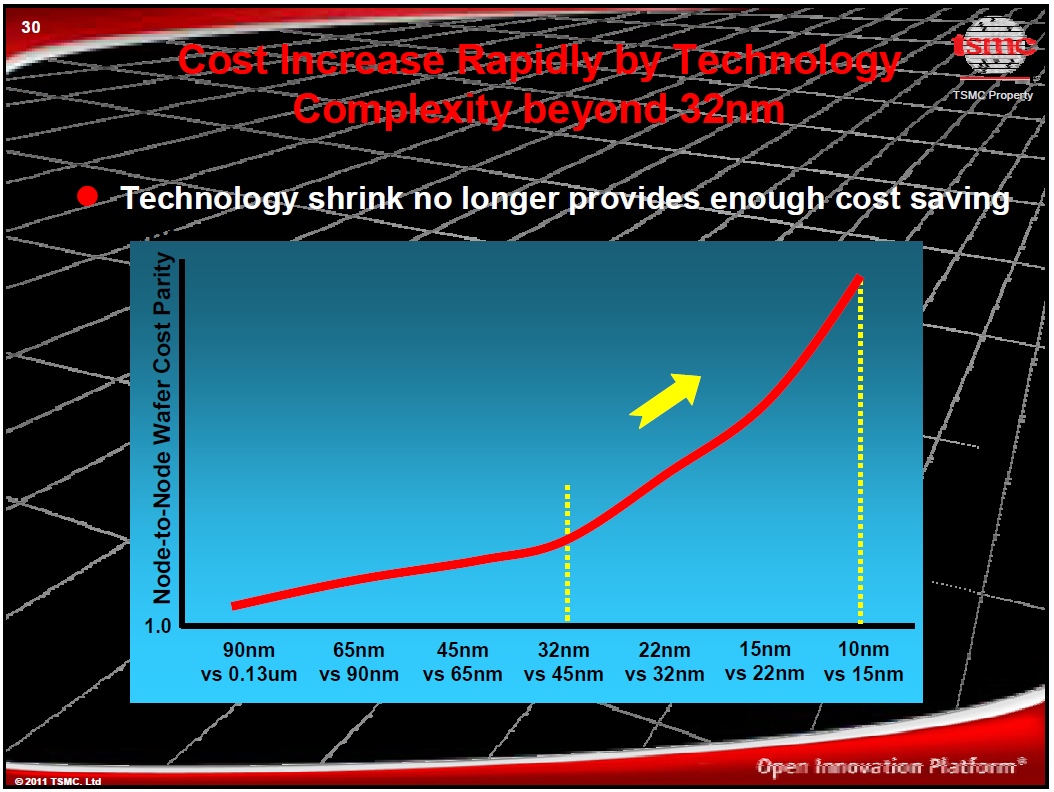

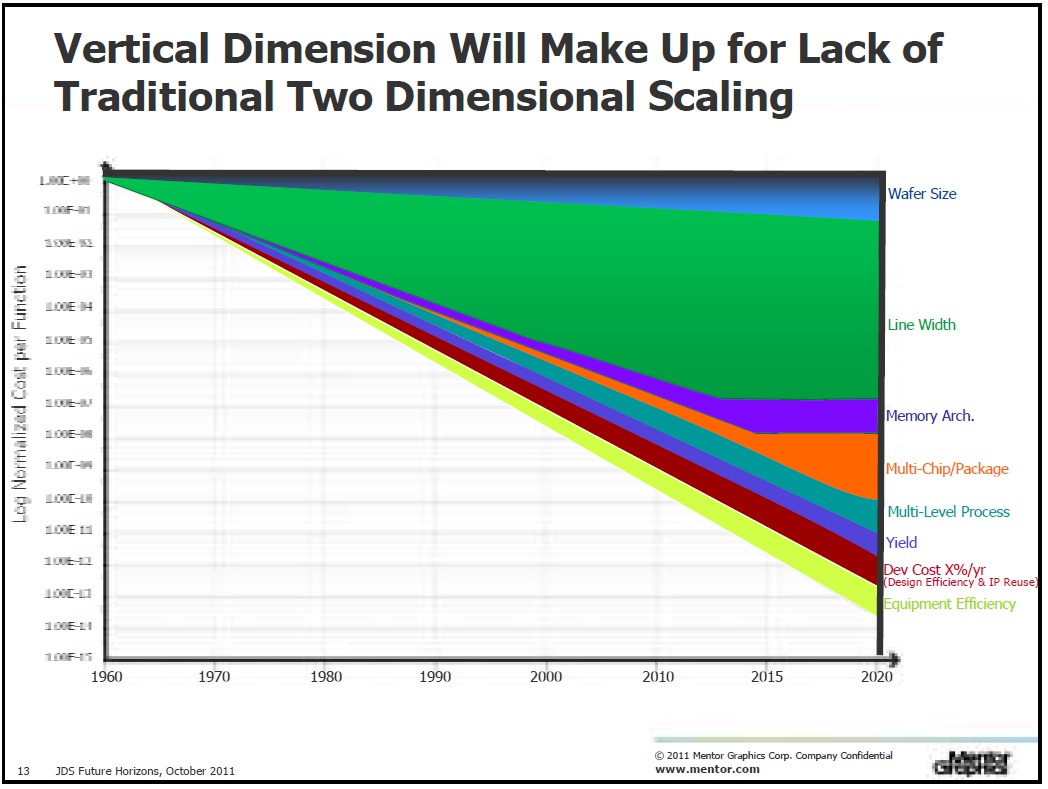

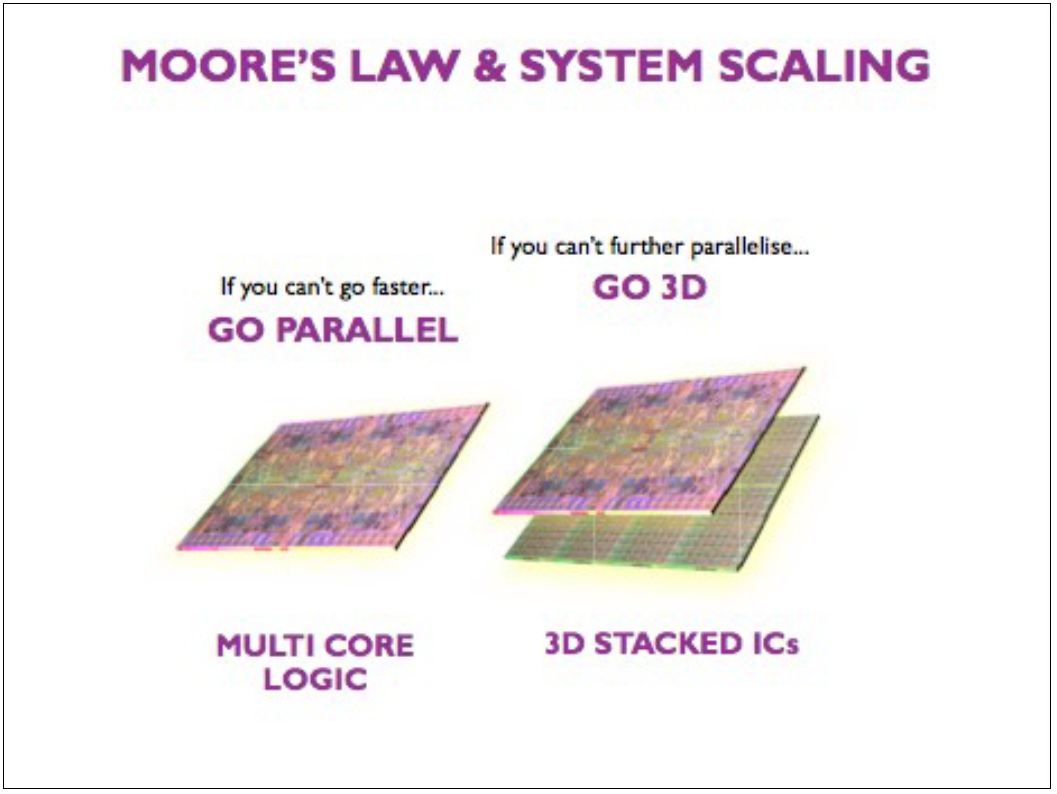

We start with two slides I pulled out of Malcolm Penn’s presentation. Clearly, we expect the industry to continue it growth path, but with sharp fluctuations of demand. As Malcolm summarized it: "Difficult (impossible) to balance capacity vs. loading.”

RSS Feed

RSS Feed