We have a guest contribution today from Paul Lim, MonolithIC 3D Inc.'s Principal Device Engineer. In this post, Paul discusses device variability and how it changes with scaling.

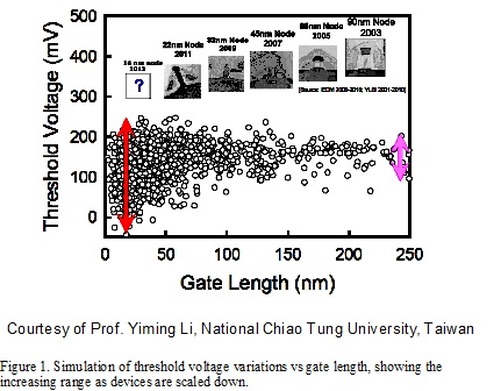

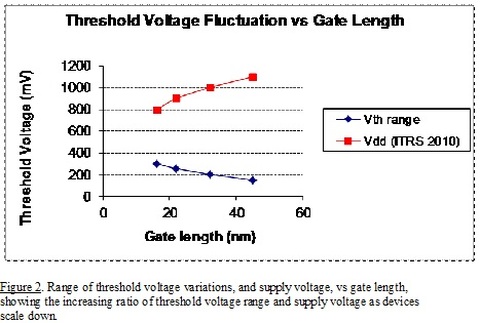

Scaling down of feature sizes such as gate lengths and widths naturally introduce device parameter fluctuations due to dimensional effects. Simply said, the smaller the device dimensions, the greater influence edge effects and other geometric variations will have on the overall device performance. In addition, we have reached the point where the discreteness of dopants and defects in the channel region has to be considered. It must be emphasized that the effects of dopant variations are not limited to just fluctuations in doping densities, but more importantly, fluctuations in the positions and distributions of the dopants as well. The compounding effect of dopant variations on the device threshold voltage is the leading cause of device manufacturing fluctuations in current technologies. This however, will be superseded by other variation sources as we continue to scale down, and will be discussed below.

The use of high-k gate dielectrics was introduced in order to reduce gate leakage due to charge tunneling through the ever thinning silicon dioxide gate dielectrics. However, this solution presented its own problems through increased interface trap densities, which were thus subject to larger variations, resulting again in an increase in device threshold voltage variability.

The recent use of metal gates is motivated by the desire to eliminate poly-depletion in poly-silicon gates and the variations inherent in them due to their granular structure. However, the existence of metal grains in the metal gates, each with their own work-function, has led to a random distribution of the gate work-function across areas of the gate rather than a uniform deterministic value. Again this contributes to the variability of device threshold voltage.

As further scaling leads to a larger ratio of the gate area to channel region, the threshold voltage variations due to gate-related fluctuations of the work-function and interface traps will start to dominate over that of dopant fluctuations in the channel. This will be especially true in devices that employ multiple gates.

FinFET structures have been promoted as being less sensitive to parameter fluctuations because of their ability to function with lower, or intrinsic, channel doping, but this only addresses variations due to dopant fluctuations. The larger gate area to channel region ratio of FinFETs exposes them to higher gate-related fluctuations, and this ratio only gets worse with further scaling. In addition, FinFETs are inherently more sensitive to the effects of dimensional fluctuations due to process variations.

A well-known expert in studying the effects of MOSFET scaling on device parameter variations is Professor Yiming Li from National Chiao Tung University in Hsinchu, Taiwan. Figure 1 is a slide from one of his presentations that shows the increase in threshold voltage variations versus scaling of gate length, and is a great summary of the trend.

RSS Feed

RSS Feed